MORE ABOUT THE LEVANT 15 By Chuck Paine

Her custom Triad Brand galvanized trailer with full trailer-length tongue extender makes launching and retrieving the boat very simple.

Why LEVANT?

Todd French had come down and sailed my smaller PAINE 14, liked it, and signed on to build future sisterships. Then I decided to scale it up, was happy with Todd’s obsession with quality, and offered the new design to him. I naturally thought it would be called the PAINE 15.

Todd signed up a first customer very quickly and made sizable investments to efficiently build more of them. Then not long ago he calls and tells me, “I want to call it the LEVANT 15”. I had a vague idea what LEVANT meant, but wondered, why?

LEVANT, in French, means “rising.” As in “rising sun”, which is why geographers refer to the Eastern shore of the Mediterranean sea as the Levant.

For a decade at least, the recreation of sailing had been in a decline. Inflation had ballooned the cost of new sailboats, the generation who love sailing are aging, motorboats have lured many of us with their convenience– despite their noise and smell– and divisive politicians and talk show hosts and a nasty little virus have distracted us from the whole idea of simply having fun.

But Todd and I believe the dark days are behind us. It’s time for something new and surprisingly fast and beautiful and reeking of class and, let’s face it, fun! The wonderful sport of sailing, a brand new yacht built by skilled Americans using the best materials ever invented, and a revival in the use of the lightest, strongest building material God ever grew on trees. Le sport de la voile est en plein LEVANT!

Aspire to owning a yacht as perfect as this? The French & Webb/ Chuckpaine.com demonstrator is for sale. Don’t miss out- it would cost 15% more at a minimum to replicate this yacht owing to Covidflation.

The LEVANT 15 is intended to be the highest quality, high performance, brand new sailboat available anywhere in the world. Quite a claim! If we have done our jobs correctly as its designer and builder, it will appeal to highly experienced sailors who have also acquired the considerable means to purchase a boat such as this and the skills to recognize that its performance is truly special. We are proud of its immediately evident appeal, and unapologetic about its price, which is as low as we can possibly make it by trimming overheads and profits to the bone. Six boats have been launched; our beautiful demonstrator is available for sale; hull number 7 is the next available building slot.

The boat is of a size that can be gotten going and put to bed very quickly. It is a joy to race with a crew of two or three. It would make an ideal racing yacht for prestigious yacht clubs to promote as their flagship racing class.

REASON I BUILT IT: I had owned the smaller version, the PAINE 14, for a few years. In all honesty, I loved that boat but I found the “PAINE 14” a little too small, so I redesigned it at 15 feet overall, and sold the sistership rights to Todd French. He has completed six so far, sold me a hull for a demonstrator boat which my company completed, and has one more under construction. He has invested in very elaborate and expensive male mold tooling to build more of them efficiently—but not “cheaply”—there is nothing cheap about this boat!

- DESIGN LIMITATIONS: I built it for myself and to be used as French&Webb’s demonstrator. There was no budget—I was willing to pay whatever it cost to make it, as I said, the finest small sailboat in the world. It had to be easy to trailer, and fit on its trailer inside my attached barn. It had to be easily maintained by myself—no boatyard. She’s very fast, and non-athletic given my age—no hiking! And it had to be beautiful, so I based the aesthetics on the aesthetically perfect Herreshoff 12½. Underwater and aloft it is completely modernized, though.

- WHY NOT LARGER? I didn’t it want to compete head to head with the Cape Cod Shipbuilding H12½ and the Doughdish, not to mention the remaining Herreshoff Manufacturing Company original woodies. They are wonderful boats. Having owned HMC hull number 1405 for over 48 years, I know. At a little bit higher in price and a little smaller in length, the LEVANT 15 won’t harm these boats’ sales, I hope.

- HOW SAFE IS IT? It is a keelboat, so it is inherently safe. But if filled with water, without compensating design features, it could sink. So it has flotation tanks forward and aft—the aft one has a waterproof hatch to keep it watertight—and if ever swamped it floats level, so it is no big deal to bail her out and get going again. (Don’t forget to have a bailer aboard). Being a very stable keelboat, you can take it out on days that any centerboarder would capsize at least once. And on really windy days it sails perfectly with a reefed mainsail and the jib rolled up, reducing its sail area by about 40%.

4. WHY IS IT SO FAST? I have found the performance of the boat to be astounding. But why? Some ideas: Large sailplan working against large stability and pretty small wetted surface. Perfect helm balance—no helm angle holding it back. Perfect foils with very narrow trailing edges—so the trailing edges have to be hand-finished epoxy/glass—too thin to come out of a conventional mold easily. But I believe the largest factor is the rig. The unstayed mast with no headstay, backstay shrouds nor spreaders reduces parasitic drag significantly—more later on this. The leading edge of the jib—the part of any sailplan that exerts the most force per square inch—is completely clean and free of a headstay, hanks, etc.

THE NARROW TRAILING EDGE OF THE KEEL. Chuck Paine photo

5. Unstayed thin-wall carbon fiber mast—light weight and small section. Makes the mast dead easy to step, too. It is held in place by a highest quality Herreshoff 12½ bronze swing-away mast gate. One old geezer can easily step the mast.

THE BRONZE MAST GATE AND JIBSHEET CAMCLEAT.

6. HULL—THE BOW. In both profile and sections, the bow is virtually identical to a Herreshoff 12½. Lots of hollow to the bow, which reduces drag a bit.

HULL—amidships. Much flatter deadrise than the H12½. Very tight (1”) radius between keel side and bottom.

HULL—AFT. The transom looks very much like that on an H12½. The deadrise of the hull at the transom is the same as it is amidships—it neither washes flatter nor more veed.

THIS PRETTY MUCH TELLS THE STORY—MUCH LESS WETTED SURFACE, LIGHTER DISPLACEMENT (1000 POUNDS VERSUS 1450), MUCH FLATTER DEADRISE FOR STABILITY . The H 12 is on the left, the Levant 15 on the right. Chuck Paine photo

7. HULL CONSTRUCTION. Epoxy saturated cold-molded wood, vacuum bagged. Four layers of 1/8” Western Red Cedar—the lightest wood available short of balsa. Glassed inside and out with 10-ounce boat cloth in epoxy. Much lighter at the same strength than fiberglass.

8. TOP STRAKE. Todd French will do whatever the owner wants. I got tired of repairing dings and gouges on my former PAINE 14, which had varnished mahogany. So on this one I used vertical grain Doug Fir, faired to the Herreshoff bulged shape, glassed over with 6 oz. epoxy glass, and painted a wood color. From more than two feet away, everyone thinks it is wood.

THE “TOP STRAKE” is painted mahogany color, so it is easy to touch-up if scraped, which does happen. The (optional) brass half-oval rubbing strip makes damage when docking or coming alongside in the dinghy far less likely.

9. RUDDER. Beautifully faired partially balanced epoxy/glass over marine plywood rudder, mounted on the transom to mimic the H12½. Streamlined rescue step aligned with the waterflow—so well faired that you are never aware it is there. If it saves an owner’s life (particularly yours) even just once, isn’t it worth the extra cost? A portion of the rudder extends forward of the pivot axis, to relieve helm force.

10. THE FORWARD EXTENDING part of the rudder might snag lobster pot lines when articulated off center. So I invented a way to make this impossible—a little cove in which the rudder swings.

THE RUDDER SWEEPS THE COVE WITH A PAPER-WIDTH OF CLEARANCE. NO LOBSTER POT LINE OR KELP IS GETTING IN THERE! Chuck Paine photo

11. WHAT IF you snag a pot buoy in a way that it can’t be shaken off? The rudder hinging is not pintles and gudgeons—it is gudgeons on both the rudder and the transom, with a “pintle rod” that can be withdrawn easily to disconnect the rudder entirely from the hull, in which case the snag goes away.

12. THE JIB is interesting. It is very high aspect, which as you know is potentially fast. But high aspect jibs have a flaw—when you let out the sheet, the clew goes out, but it also goes up. So the top half of the jib twists off, and luffs, and the bottom is overtrimmed, and stalls. Not on this boat. The three full-height battens, parallel to the luff, prevent this twisting off. Because of the bias strength of the sailcloth, they prevent the foot from rising as the sheet is let out. The jib is roller-furled using a gorgeous polished bronze furler and upper swivel from England. The battens, being parallel to the luff, have no ill effect upon the roller-furling. They permit the jib to be easily reefed without creating the baggy shape all jibs without these battens develop.

THE PHOTO AT LEFT SHOWS HOW THE JIB BATTENS WORK. THE LEADING EDGE OF THE ENTIRE JIB IS WORKING, ALL THE WAY TO THE TOP. THE BOAT IS ON A REACH, NOT A BEAT, SO THE SHEETS ARE LET OUT A BIT. ON ANY OTHER BOAT, THE TOP HALF OF THE JIB WOULD BE LUFFING AND THE BOTTOM STALLED. Norm Talbot photo

THIS PHOTO SHOWS THE BOAT WITH BOTH THE MAINSAIL AND JIB REEFED. NOTE THAT THE JIB CAN BE REEFED TO ANY SIZE YOU WANT, AND THE THREE FULL-HEIGHT BATTENS PREVENT IT FROM GETTING BAGGY

13. THE MAST is carbon fiber. To lower the CG and reduce its size and weight. Just look at how long and slender that hollow mast is! It is light enough that one 79-year old weakling can swing it up into place and take it down again. It weighs 23 pounds with the halyards in place. I heartily support the mast builder—Forte Spars of Ledyard, Connecticut. They build great carbon spars:

HARD ALEE! Art Paine photo

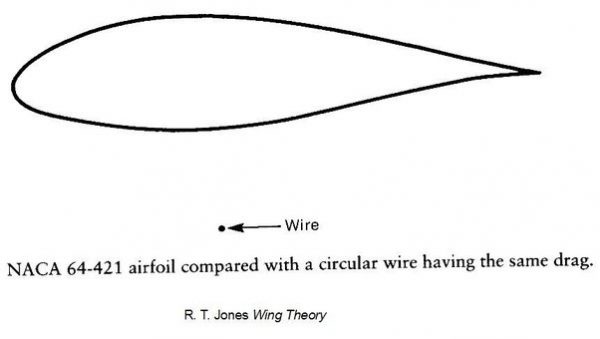

14. MORE ABOUT SHROUDS, ETC. There is a page in one of the aerodynamics books that points out that the parasitic drag of a small diameter round object (shroud) is the same as a HUGE object of the proper foil shape.  (Shown at left). And Jay Paris has written that the parasitic drag of a ½” round wire is the same as that of a Boeing 747 wing, at the same length. Not sure that he is right, but we all know parasitic drag is, well, a real drag. So eliminating sidestays is a good thing. And of course there is no headstay as well—like many roller-furled jibs the LEVANT 15 has no separate headstay. Imagine, looking at the illustration on the left, what the presence of a headstay and a hanked-on jib just behind it does to a jib’s effectiveness!

(Shown at left). And Jay Paris has written that the parasitic drag of a ½” round wire is the same as that of a Boeing 747 wing, at the same length. Not sure that he is right, but we all know parasitic drag is, well, a real drag. So eliminating sidestays is a good thing. And of course there is no headstay as well—like many roller-furled jibs the LEVANT 15 has no separate headstay. Imagine, looking at the illustration on the left, what the presence of a headstay and a hanked-on jib just behind it does to a jib’s effectiveness!

15. MAST HOOPS VERSUS TRACKS AND SLIDES. This boat uses Velcro straps in place of tracks and slides on the mainsail luff. It takes a mere few seconds to attach the mainsail luff to the mast using these Velcro straps—the primary motivation for using them. But there is another totally unexpected benefit. The Velcro straps, like mast hoops, permit the luff tape of the mainsail to move over to the leeward side of the mast every time you tack. This “cleans up” the airflow on the leeward, low pressure, side of the mast, increasing lift. Plenty of airplanes have recognized this phenomenon, with what looked like clumsy leading edge slats that hang down from the forward edge on takeoff and landing, and on the Cessna 402C and the world’s most beloved airplane—the Spitfire—aft flaps that merely articulate downward from beneath the trailing edge. As long as you leave the negative pressure (in the case of boats, leeward) side clean, lift is increased. It has taken time and a number of iterations to get the straps right—if they are allowed to droop, they can jam on the mast. So people who want to copy it are encouraged to contact me first so I can help them get it right.

- Strap Open

- Strap Closed (Chuck Paine photos)

16. ERGONOMICS of the cockpit. Many people have written that the ergonomics of the Herreshoff 12½ cockpit are the epitome of human seating. And they are right. What matters are the angle of the seat to horizontal, the angle of the seatbacks (the coamings) to vertical, but most important, the distance between the small of your back and the edge of the opposite seat, upon which you can brace your feet. I have copied this on the slightly smaller LEVANT 15, simply by reducing the width of the covering boards, from 3” on the H12½, to 1½” on the LEVANT 15. The distance from seatback to the opposite seat is nearly the same on both designs. Don’t mess with perfection.

17. CONVENIENT SHEETING. The jib and main both have camcleats. The forward one lets you take the end of the jibsheet aft to where you sit, and you can trim and release it from the helm.

18. THE SAILS. By trial and error I have discovered that the Bristol, RI loft of Quantum Sailmakers made exquisite sails comparable to those of North and Doyle Sails, and their customer service and value for money are excellent. Contact Steve Thurston, (401) 254-0970. www.thurstonsails.com This loft has worked with me to perfect the Velcro attachment straps and vertical jib battens, and has perfected the shape of the mainsail.

IT WAS ONLY BLOWING ABOUT 7 TO 8 KNOTS WHEN THESE PHOTOS WERE TAKEN. MOST OF THE TIME THE BOAT WAS GOING AT HULL SPEED.

NOT MUCH WIND, BUT LOOK AT HER GO! LOOSENING THE MAIN OUTHAUL LETS THE FOOT ROACH INCREASE THE CAMBER OF THE LOWER PART OF THE MAINSAIL. Art Paine photo

TODD FRENCH is the builder of this beautiful, high performance keel sailboat, the LEVANT 15.

WANT TO SEE HER SAILING? Here are two videos to give you some idea:

FOR QUESTIONS RELATED TO THE YACHT:

A brief opportunity, never to be repeated: The exquisite demonstrator yacht loaded with options shown in these photos and videos is for sale this coming Spring, and once it is gone, it’s gone. It is being sold, entirely properly, for its cost to build at the time of its construction, despite the fact that the recent Covidflation would make it at least 15% more costly to reproduce. Act fast- avoid a bidding war- and buy this boat if you are in the position to do so. You will never regret it.

Further information may be obtained from this website and:

Builder’s website: www.frenchwebb.com

(Note there are more videos on the French & Webb website that show how well this boat sails.)

Phone: (207) 323-2550

FOR QUESTIONS RELATED TO THE DESIGN: CHUCKPAINE.COM LLC

Phone: (207) 691-5195

Email: paineyot@aol.com

For those who own or have owned a Chuck Paine design, and those who aspire to owning one someday, here is a fun Facebook Group where you can meet and greet others with similar interests.

I have (with some help) created a Facebook group where people who like the boats I’ve designed over the years can meet and discuss. Take a look and consider joining and/or sharing with your boating friends. Just click the blue text and join. https://www.facebook.com/groups/424532172574012/ “

I’ll be in the background serving as “moderator”. I’m hoping that many of the well- over- 1000 owners of a Paine design will enjoy belonging to this group.

Chuck Paine